Custom Merino Wool Socks: A Guide to Bulk Orders and Minimum Quantities for Your Brand

Unlocking Brand Potential with Custom Merino Wool Socks

In a competitive market, creating a unique brand identity is paramount. Custom merino wool socks offer a distinctive and high-quality way to promote your business, team, or event. They are more than just an accessory; they are a statement of quality and attention to detail. However, venturing into custom manufacturing introduces important concepts like bulk orders and Minimum Order Quantity (MOQ). Understanding these terms is the first step toward a successful and profitable project.

What is a Minimum Order Quantity (MOQ)?

A Minimum Order Quantity (MOQ) is the fewest number of units a manufacturer is willing to produce and sell in a single order. This number can be based on the quantity of units or the total value of the order. For example, a manufacturer might require an order of at least 200 pairs of socks per design. This is a standard practice in the manufacturing industry, especially for custom products, as it ensures that each production run is financially viable for the supplier.

Why MOQs Are Essential for Custom Merino Wool Socks

Setting up production for custom goods isn't as simple as grabbing an item off a shelf. For custom merino wool socks, the MOQ is necessary to cover significant upfront costs. This includes:

- Raw Material Sourcing: Merino wool is a premium material, and suppliers of this raw fiber often have their own MOQs.

- Custom Dyeing: Creating a specific Pantone color for your brand requires dyeing a minimum amount of yarn.

- Knitting Machine Setup: Each unique design requires specialized setup and programming of industrial knitting machines. These setup costs are fixed, whether producing 50 pairs or 500.

- Labor and Administrative Costs: Every order, regardless of size, involves administrative, packaging, and shipping coordination tasks. MOQs ensure these overheads are covered, protecting the manufacturer's profit margin.

Essentially, MOQs allow manufacturers to achieve economies of scale, which spreads the fixed costs over a larger number of units, ultimately lowering the cost per piece.

MOQ vs. Bulk Orders: What's the Difference?

Though often used interchangeably, MOQ and bulk orders refer to different concepts. An MOQ is a requirement set by the supplier—the minimum you must buy. A bulk order, on the other hand, is simply a large order placed by a customer to gain benefits like lower per-unit pricing. While an order must meet the MOQ to be accepted, a bulk order is often much larger than the MOQ to maximize cost savings and convenience.

The Buyer's Advantage: Benefits of Meeting the MOQ

While an MOQ might seem like a barrier, meeting it offers significant advantages to you, the buyer:

- Cost Savings: The most significant benefit of ordering in bulk is a lower price per unit. This improves your profit margin if you plan to resell the socks.

- Reduced Shipping Costs: Placing one large order instead of multiple small ones drastically reduces overall shipping and handling fees.

- Brand Consistency: A single production run ensures that all your socks have consistent color, quality, and feel, which is crucial for brand integrity.

- Inventory Control: Having a healthy stock of your custom socks ensures you can meet demand without the risk of running out.

| Feature | Small Order (Below MOQ) | Bulk Order (Meeting/Exceeding MOQ) |

|---|---|---|

| Per-Unit Cost | High (if available at all) | Low |

| Availability | Not usually offered | Guaranteed Production |

| Consistency | N/A | High |

| Shipping Fees | Higher cumulative cost | Lower single-shipment cost |

How to Calculate Your Custom Sock Order

There isn't a universal formula for calculating the perfect order size, as needs vary. However, before placing an order, consider:

- Demand Forecasting: Analyze your needs. Is this for a one-time event, an ongoing retail product, or corporate gifts?

- Sizing Breakdown: Don't forget to plan for different sock sizes. A typical breakdown might be 10% Small, 40% Medium, 40% Large, and 10% Extra-Large.

- Break-Even Point: Determine how many pairs you need to sell or distribute to cover your costs.

- Storage: Ensure you have adequate space to store the inventory. Holding costs can add up if items don't move as planned.

Our Transparent Manufacturing Process

Understanding the journey of your custom socks helps clarify why MOQs are a necessary part of the process. Our supply chain is built on transparency and quality.

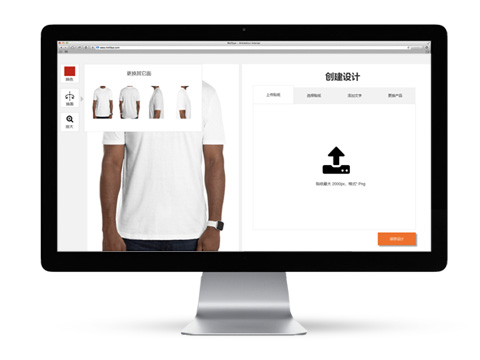

- Design & Consultation: It starts with your vision. We help refine your design into a factory-ready tech pack.

- Yarn Sourcing & Dyeing: We source high-quality, ethically-farmed merino wool from dedicated farms and custom-dye it to match your brand's color palette.

- Sampling: Before full production, we create a sample for your approval to ensure the stitch, colors, and fit are perfect.

- Knitting & Finishing: Once approved, your order goes into production on our advanced knitting machines, followed by finishing touches like linking and washing.

- Quality Control & Shipping: Every pair is inspected before being packaged and shipped to you.

Navigating MOQs as a Startup or Small Business

High MOQs can feel daunting for new or small businesses. However, there are smart strategies to make it work:

- Negotiate with the Supplier: Many suppliers are willing to negotiate, especially if you show a plan for long-term partnership. Offering to pay a slightly higher per-unit price might convince them to accept a smaller initial order.

- Group Buys: Collaborate with other small businesses to place a joint order that meets the MOQ.

- Pre-Order Campaigns: Gauge interest and secure funding by running a pre-order campaign before placing your manufacturing order.

- Simplify Your Design: A simpler design with fewer colors or custom elements may have a lower MOQ.

What If You Can't Meet the MOQ?

If you truly cannot meet the minimum, ask about alternatives. Some manufacturers might be producing a similar sock for another client and could add your smaller order to that run. Others may offer simpler stock products that can be customized with packaging. For apparel, some manufacturers specialize in low MOQ production, often starting at 50 to 100 units.

Maximizing the Value of Your Bulk Sock Order

Once you have your custom merino wool socks, their value extends far beyond just wearing them. Consider these uses:

- Promotional Giveaways: High-quality socks make a memorable and useful promotional item.

- Corporate Gifts: Welcome new employees or thank loyal clients with a practical and premium gift.

- E-commerce Merchandise: Add a unique, high-profit-margin item to your online store.

- Team Uniforms: Unify your sports team, club, or corporate group with matching socks.

Ready to Create Your Custom Merino Wool Socks?

Understanding bulk orders and minimum order quantities demystifies the custom manufacturing process and empowers you to make informed decisions for your brand. By balancing cost, quantity, and quality, you can leverage custom merino wool socks to create a lasting impression. Ready to start your project? Contact us today to discuss your design and production needs.